The construction industry stands at a pivotal moment, embracing a wave of digital transformation to address persistent challenges in efficiency, cost management, and safety. In this evolving landscape, digital twins have emerged as a powerful technology, promising to revolutionize how projects are conceived, executed, and maintained. Their increasing prominence signifies a fundamental shift towards data-driven decision-making and proactive management throughout the lifecycle of built assets. This report delves into the intricacies of digital twins in construction, exploring their definition, integration with existing technologies, tangible benefits, real-world applications, platform comparisons, adoption hurdles, and the exciting trajectory of their future development.

Decoding the Digital: What Exactly is a Digital Twin in Construction?

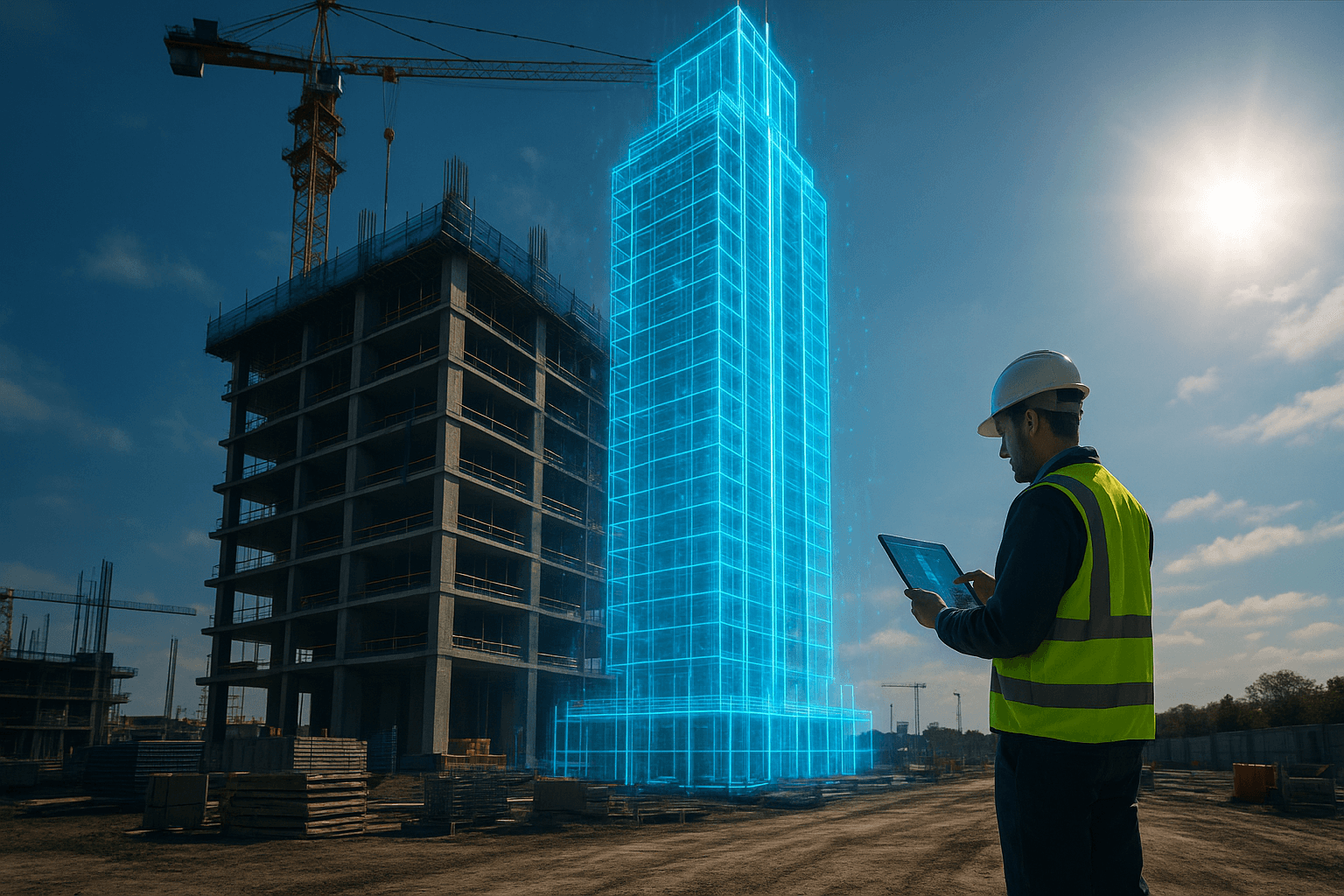

At its core, a digital twin in the construction sector is a dynamic virtual representation of a physical entity, be it a building, a piece of infrastructure, or an entire construction site. This virtual replica mirrors its physical counterpart in near real-time, establishing a seamless bridge between the physical and digital worlds. Data flows continuously between these two realms, allowing the digital twin to exist concurrently with the physical asset and reflect its current state. This is achieved through the integration of data from a multitude of sources, including real-time feeds from sensors embedded in the physical asset, detailed information from Building Information Models (BIM), and data from other Internet of Things (IoT) devices. By consolidating these diverse data streams, the digital twin provides a comprehensive and up-to-date understanding of the construction project.

While the concept of a digital twin shares similarities with other digital representations in construction, such as BIM, there are crucial distinctions. BIM primarily focuses on the design and construction phases of a project, utilizing predominantly static data to create a detailed digital model. Digital twins, however, extend their reach throughout the entire lifecycle of an asset, from initial design to ongoing operations and maintenance. They are characterized by their dynamic nature, continuously updating with real-world data to provide a living model of the asset. As Giacomo Lee aptly put it, "Where a BIM constructs and designs, a twin manages and maintains; like a real-life asset, it never stops being affected by what's around it". Thus, while BIM lays the foundation with design and construction data, the digital twin builds upon this by incorporating real-time operational data, transforming a static model into a dynamic and insightful tool.

The sophistication of a digital twin can also vary significantly. Research suggests a maturity model for digital twins, indicating a progression through different levels of capabilities. These levels typically range from basic digitization and visualization of data to more advanced stages involving sophisticated analysis, predictive capabilities, and even autonomous decision-making. This implies that organizations can adopt digital twin technology incrementally, starting with foundational applications and gradually advancing towards more complex and value-driven implementations based on their specific needs and technological readiness. Ultimately, a digital twin in construction serves as more than just a 3D model; it acts as a dynamic, data-rich replica that empowers stakeholders with real-time insights and the ability to monitor, analyze, and potentially predict the behavior of a physical construction asset throughout its entire existence.

The Power Trio: Integrating BIM, Real-Time Data, and Project Schedules for a Holistic View

The true power of a digital twin in construction emerges from the synergistic integration of three key elements: Building Information Models (BIM), real-time sensor data, and project schedules. These components converge within the digital twin platform to provide a comprehensive and dynamic virtual representation of the construction project.

Building Information Models (BIM) serve as the bedrock of the digital twin, providing a rich and detailed digital blueprint of the project. BIM encompasses not only the three-dimensional geometry of the building or infrastructure but also a wealth of semantic information regarding the materials, specifications, and relationships between different components. This foundational data from the BIM model provides the essential context and structure for the digital twin. As construction progresses and real-world data becomes available, the static information within the BIM model evolves into a "living" representation, constantly updated to reflect the as-built conditions.

Complementing the design intelligence of BIM is the continuous stream of data emanating from real-time sensors deployed across the construction site, embedded within equipment, and even integrated into building materials. These IoT sensors capture a diverse range of live data, offering granular insights into various aspects of the project. Examples of such data include temperature and humidity levels, measurements of structural load and stress, performance metrics of construction equipment, and even the location of workers on site. This real-time data is then seamlessly integrated into the BIM model, populating the digital twin with up-to-the-minute information about the physical asset's status and its surrounding environment.

The third crucial element in this powerful trio is the integration of project schedules. These schedules, outlining project timelines, key milestones, and the allocation of resources, provide the temporal dimension to the digital twin. By incorporating this scheduling data, the digital twin can visualize the project's progress against the planned timeline in real-time. This allows project managers to monitor whether the construction is proceeding according to schedule and to identify any potential delays or bottlenecks by comparing the virtual progress with the intended plan.

The convergence of BIM's detailed design information, real-time sensor data reflecting the current physical state, and project schedules outlining the planned progress creates a "single source of truth" for all project stakeholders. This unified platform fosters unparalleled transparency, enabling architects, engineers, contractors, and owners to access the most current and relevant information in a contextualized and easily understandable format. By breaking down traditional data silos, this holistic view facilitates enhanced communication and collaboration among different teams, ultimately leading to better-informed decision-making throughout the entire project lifecycle, from the initial design phase to the long-term operations and maintenance of the completed asset.

Unlocking Tangible Benefits: How Digital Twins are Revolutionizing Construction

The adoption of digital twins in construction is not merely a technological novelty; it unlocks a range of tangible benefits that are revolutionizing how projects are managed and executed. Among the most significant advantages are the enhanced capabilities for clash detection and resolution, smart resource management leading to reduced waste, and the creation of safer construction environments through proactive hazard mitigation.

One of the most immediate and impactful benefits of digital twins is their ability to pinpoint potential problems before they even materialize on the physical construction site. By creating a detailed virtual representation of the project, digital twins enable the early identification of clashes or conflicts between different design elements, such as architectural components, structural frameworks, and mechanical, electrical, and plumbing (MEP) systems. Through sophisticated simulation and visualization within the digital environment, project teams can detect these spatial conflicts during the design phase, long before construction begins. Resolving these clashes within the digital model is significantly more cost-effective and time-efficient than addressing them on-site, where rework can lead to substantial expenses and project delays. This proactive approach minimizes the need for costly rework, reduces material waste from incorrect installations, and helps keep projects on schedule. In fact, a study published in the Construction Management and Economics journal indicated that BIM-based clash detection, a key component of digital twins, can save up to 20% of the contract value in major infrastructure projects.

Beyond preventing design conflicts, digital twins also empower construction teams with smart resource management capabilities. By integrating project schedules and real-time data on material usage, equipment availability, and workforce deployment, digital twins facilitate better planning and allocation of all essential resources. The ability to track resource utilization in real-time, often through sensor data integrated into the digital twin, provides valuable insights into efficiency and potential bottlenecks. Furthermore, simulations within the digital twin environment can help optimize logistics, procurement processes, and overall supply chain management, ensuring that the right resources are available at the right time and in the right place. This enhanced visibility and control over resources leads to a significant reduction in waste by accurately forecasting material needs and identifying any inefficiencies in resource allocation. The use of digital twins can improve the procurement process and ease supply chain holdups, fostering better allocation of resources and physical assets.

Creating a safer construction environment is another paramount benefit offered by digital twins. By enabling the simulation of hazardous scenarios and the identification of potential risks before they occur in the physical world, digital twins allow project teams to proactively develop and implement effective safety protocols. Real-time sensor data can be utilized to continuously monitor site conditions, such as air quality, temperature fluctuations, and structural stability, providing immediate alerts to potential hazards and ensuring worker safety. Moreover, digital twins offer a platform for improved safety training through immersive virtual simulations of construction sites and hazardous operations, allowing workers to familiarize themselves with potential risks in a safe and controlled environment. Remote site monitoring through digital twins also allows project managers and safety personnel to oversee safety procedures more effectively, even without being physically present on site. By minimizing the time humans spend in hazardous conditions and enabling preventative maintenance through real-time monitoring, digital twins contribute significantly to reducing the likelihood of accidents and injuries on construction sites.

The benefits of digital twins are inherently interconnected. For example, early clash detection not only saves costs and time but also contributes to a safer work environment by preventing potential structural or system conflicts that could lead to accidents. Similarly, efficient resource management reduces waste, aligning with sustainability goals, while real-time safety monitoring directly contributes to improved worker well-being and reduced project risks. This interconnectedness underscores the holistic value proposition of digital twin technology in creating a more efficient, cost-effective, and, most importantly, safer construction industry.

From Vision to Reality: Real-World Examples and Their Impact

The transformative potential of digital twins in construction is not just theoretical; it is being realized in numerous real-world projects, yielding significant benefits in terms of efficiency, cost savings, and improved outcomes. Examples from stadium construction and complex infrastructure projects provide compelling evidence of this impact, often with documented metrics showcasing substantial improvements.

In the realm of stadium construction, digital twins are proving invaluable for optimizing both the building process and the subsequent fan experience. SoFi Stadium in Los Angeles, a state-of-the-art venue, serves as a prime example. The stadium utilizes a comprehensive digital twin for daily management, enabling the optimization of fan experiences through features like personalized wayfinding and reduced wait times at concession stands. Furthermore, the digital twin aids in identifying operational inefficiencies, such as detecting and addressing elevated temperature settings within the building. The Vice President of Facility Operations at SoFi Stadium noted that the digital twin has become an extremely useful time-saving mechanism in their day-to-day operations. Similarly, the Camp Nou stadium, home to FC Barcelona, has been used as a testbed for urban digital twin frameworks, demonstrating the potential for simulating visitor flow and optimizing stadium operations.

Complex infrastructure projects are also benefiting significantly from the implementation of digital twins. The Crossrail project in London, now known as the Elizabeth Line, stands as a landmark example. This massive undertaking utilized BIM to create a common data environment and a "virtual version" of the entire railway system. This digital representation facilitated the simulation of various scenarios, the early identification of potential issues, the optimization of designs, and enhanced collaboration among the numerous stakeholders involved. The project reportedly benefited from improved safety, reduced costs, and increased productivity through the use of this digital twin approach. Beyond railway projects, digital twins are also being leveraged for the monitoring and maintenance of other critical infrastructure, such as bridges and transportation networks. For instance, the Minnesota Department of Transportation anticipates saving USD 4 million annually by using Bentley Systems' iTwin platform for more efficient bridge inspections.

The tangible benefits of digital twins are further substantiated by documented cost savings across various projects. Studies suggest the potential for cost reductions of up to 20% through the implementation of digital twin technology. Gilbane, a construction company, reported achieving 25% to 30% savings in both time and cost by utilizing Matterport digital twins in their design-build programs. Another case highlighted that adopting digital twins on a specific project resulted in savings of $15 million. Furthermore, predictions indicate that the widespread adoption of digitalization, with digital twins playing a key role, could lead to substantial annual global cost savings in the design, engineering, construction, and operations phases of projects.

In addition to cost savings, digital twins are also contributing to significant reductions in project cycle times. Hickory Construction Company reported a 15% reduction in construction time through the application of digital twin technology. The ability to make faster and more informed decisions, coupled with the reduction in rework resulting from early clash detection and proactive problem-solving, directly contributes to shorter project completion times. Gilbane's reported time savings of 25% to 30% further underscore this benefit. These real-world examples across diverse construction projects provide compelling evidence of the practical value of digital twins, demonstrating their capacity to deliver significant cost reductions and accelerate project timelines, thereby validating their transformative potential within the industry.

Choosing Your Digital Partner: Exploring Leading Platforms (Azure, Bentley, Autodesk)

As the adoption of digital twins in construction gains momentum, several leading technology platforms have emerged to support their creation and implementation. Among the most prominent are Azure Digital Twins from Microsoft, the iTwin platform from Bentley Systems, and Autodesk Tandem. Each platform offers unique features and integration capabilities tailored to different aspects of the construction lifecycle and technology ecosystems.

Azure Digital Twins is a comprehensive platform that enables the modeling and creation of digital representations for a wide range of connected environments, including buildings, infrastructure, and even entire cities. It utilizes an open modeling language called Digital Twins Definition Language (DTDL), promoting flexibility and interoperability. The platform seamlessly integrates with other Azure services, such as data analytics and IoT Hub, providing a robust environment for building and managing complex digital twin solutions. For example, Heijmans, a Dutch construction company, leverages Azure Digital Twins for gaining deeper insights into existing infrastructure and offering more efficient maintenance services. Microsoft itself utilizes Azure Digital Twins to manage smart building technology in its recently renovated buildings, showcasing its capabilities in optimizing building operations.

Bentley Systems, a well-established provider of software solutions for infrastructure engineering, offers its iTwin platform for the creation, visualization, and analysis of infrastructure digital twins. The iTwin platform is designed to connect the physical and digital worlds, enabling users to capture reality data and integrate it with engineering models. It supports various Bentley software applications and facilitates collaboration among project stakeholders. The Minnesota Department of Transportation expects to achieve significant cost savings by using Bentley iTwin for bridge inspections. Similarly, Beca, an engineering consultancy, utilizes the iTwin IoT platform for real-time monitoring during the reinstatement of the Christ Church Cathedral, highlighting its effectiveness in structural health monitoring.

Autodesk, a leading provider of design and construction software, offers Autodesk Tandem as its digital twin platform. Tandem is specifically designed to bridge the gap between the design and construction phases, leveraging the rich data contained within BIM models to create data-rich digital replicas of buildings. The platform focuses on providing facility owners and managers with a user-friendly interface to navigate their buildings within a true-to-life 3D model, facilitating efficient operations and maintenance. NV5, a professional services firm, utilizes Autodesk Tandem to enhance operational efficiency and reduce costs for its clients across various industries. Metro Istanbul, the operator of the Istanbul Metro, has reported significant reductions in energy consumption and maintenance costs after adopting Autodesk Tandem for its stations.

To provide a clearer comparison, the following table summarizes the key aspects of these leading digital twin platforms:

| Platform | Key Focus | Integration With | Open Standards Support | Example Use Cases |

|---|---|---|---|---|

| Azure Digital Twins | Broad IoT environments | Azure services, IoT Hub | DTDL | Infrastructure maintenance, Smart buildings |

| Bentley iTwin | Infrastructure lifecycle | Bentley software applications | IFC | Bridge inspection, Structural health monitoring |

| Autodesk Tandem | Building operations | Autodesk software (Revit, IFC) | IFC | Operational efficiency, Energy & maintenance cost reduction |

Navigating the Path to Adoption: Challenges and How to Overcome Them

While the benefits of digital twins in construction are compelling, their widespread adoption is not without challenges. Several hurdles need to be navigated to fully realize the potential of this transformative technology.

One of the primary challenges is the high initial cost associated with implementing a digital twin solution. This includes investments in software licenses, the deployment of necessary hardware such as sensors and scanners, and the provision of adequate training for staff. To mitigate this, organizations can consider a phased approach to adoption, starting with smaller, less complex projects to prove the value and manage the initial financial outlay.

Another significant challenge lies in data management and integration. Digital twins rely on the seamless flow of data from various sources, often in disparate formats. Integrating BIM data, real-time sensor data, project schedules, and other relevant information can be complex and requires robust data management strategies and tools. Emphasizing data standardization and ensuring interoperability between different systems are crucial steps in overcoming this challenge. The use of digital construction platforms that act as centralized hubs for all project data can also help streamline this process.

The construction industry also faces a skill gap in terms of professionals who possess the expertise needed to develop, implement, and manage digital twin technologies. Furthermore, there can be resistance to adopting new technologies within organizations, particularly if the benefits are not clearly understood or if the implementation process is perceived as disruptive. Addressing this requires a focus on training and development programs to equip the workforce with the necessary skills. Demonstrating the tangible value and return on investment of digital twins through pilot projects and case studies can also help overcome resistance and foster a more receptive organizational culture.

Data security and privacy are also critical concerns when dealing with the vast amounts of data collected by digital twins. Robust data management systems and stringent security measures are essential to protect sensitive project information and ensure compliance with relevant regulations.

Finally, the current lack of industry-wide standards for digital twins poses a challenge to interoperability and the seamless exchange of data between different platforms and stakeholders. Efforts are underway to establish common taxonomies, data models, and exchange protocols, which will be crucial for facilitating broader adoption and maximizing the benefits of digital twin technology across the construction industry.

Addressing these challenges requires a multi-faceted approach that encompasses strategic investment, a focus on data management and interoperability, workforce development initiatives, robust security protocols, and industry-wide collaboration to establish necessary standards. By proactively tackling these hurdles, the construction industry can pave the way for a more widespread and successful adoption of digital twins.

The Future is Now: Emerging Trends and Opportunities in Construction Digital Twins

The application of digital twin technology within the construction sector is rapidly evolving, with several exciting trends and opportunities on the horizon that promise to further transform the industry.

One significant trend is the increasing integration of digital twins with Extended Reality (XR) technologies, including virtual reality (VR) and augmented reality (AR). This integration allows for more immersive and intuitive experiences in various construction processes, such as design reviews, progress inspections, and safety training. XR enables stakeholders to virtually walk through a digital twin of a project, facilitating better understanding, collaboration, and decision-making.

Artificial Intelligence (AI) and Machine Learning (ML) are also playing an increasingly vital role in the advancement of digital twins. AI and ML algorithms enhance the predictive capabilities of digital twins, enabling them to analyze vast amounts of data to identify patterns, predict potential issues like equipment failures or structural stresses, and optimize building performance throughout its lifecycle. This leads to more proactive maintenance strategies, improved risk assessment, and enhanced operational efficiency.

The emergence of Digital Twin as a Service (DTaaS) and cloud-based solutions is making this technology more accessible and affordable for businesses of all sizes. Cloud platforms offer the benefits of scalability, flexibility, and remote access, reducing the need for significant upfront infrastructure investments and democratizing the use of digital twins across the industry.

The application of digital twin technology is also expanding beyond individual projects to encompass entire cities and urban environments. Smart city initiatives are leveraging digital twins for urban planning, infrastructure management, traffic optimization, and sustainability efforts, enabling a more holistic and data-driven approach to city development and operation.

Finally, there is a growing emphasis on utilizing digital twins to promote sustainability and improve environmental management within the construction sector. By accurately modeling energy consumption, material usage, and the environmental impact of construction processes, digital twins enable companies to make more informed decisions that align with sustainability goals and reduce their carbon footprint.

These emerging trends point towards a future where digital twins become even more intelligent, connected, and accessible, further solidifying their role as a cornerstone of the modern construction industry.

Conclusion: Embracing the Virtual Backbone for a Smarter Construction Industry

Digital twins have moved from a nascent concept to a tangible reality, offering a transformative approach to the construction industry. By integrating the detailed design intelligence of BIM, the real-time insights from sensor data, and the temporal context of project schedules, digital twins provide a holistic and dynamic virtual representation of construction projects. This powerful tool unlocks significant benefits, including the proactive identification and resolution of design clashes, the optimization of resource management for enhanced efficiency and reduced waste, and the creation of safer work environments through the simulation and mitigation of potential hazards.

Real-world examples in both stadium construction and complex infrastructure projects have demonstrated the practical value of digital twins, often accompanied by documented metrics of substantial cost savings and accelerated project timelines. While challenges related to initial costs, data management, skill gaps, security, and standardization exist, the industry is actively working to overcome these hurdles.

Looking ahead, the future of digital twins in construction is bright, characterized by exciting trends such as integration with extended reality for immersive experiences, the application of artificial intelligence and machine learning for advanced analytics and prediction, the rise of cloud-based solutions for increased accessibility, the expansion to smart cities for holistic urban planning, and a growing focus on leveraging this technology to drive sustainability and environmental responsibility. As the virtual backbone of modern construction, digital twins are empowering industry professionals to build more efficiently, cost-effectively, and safely, paving the way for a smarter and more sustainable future for the built environment. The time for construction professionals to embrace this technology and prepare for the future of digital construction is now.